Copy of Presentation for Comments

Paul Kern and Chris Shartrand

03 00 AM ,Wed, Sep 16 2015

Background Knowledge

- Aluminum Alloy consisting of Zinc, Magnesium, Copper, Iron, Silicon, Manganese, Chromium, Zirconium, and Titanium.

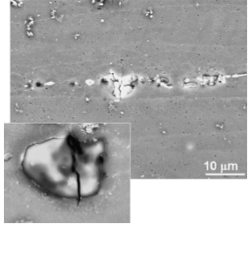

- During processing it is common for μm-sized particles to become ingrained in the matrix

- Deformation can cause particles to become cracked or detached

- Cracks combined with stress can lead to failure in the alloy

Importance

- AA7075 is commonly used in the construction of airframes

- Product failure = Costly

- Improved modeling can lead to prediction of microstructures that have a higher probability of cracking.

- Quantification of product quality.

The Microstructure

- Particles are very stiff

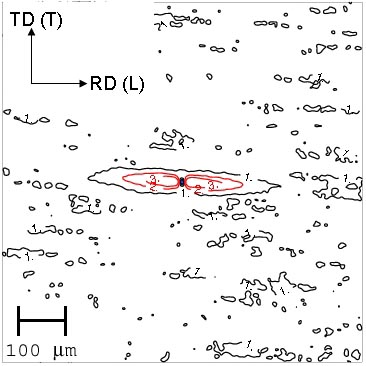

- Tend to cluster and form “stringers” along the direction of the roll

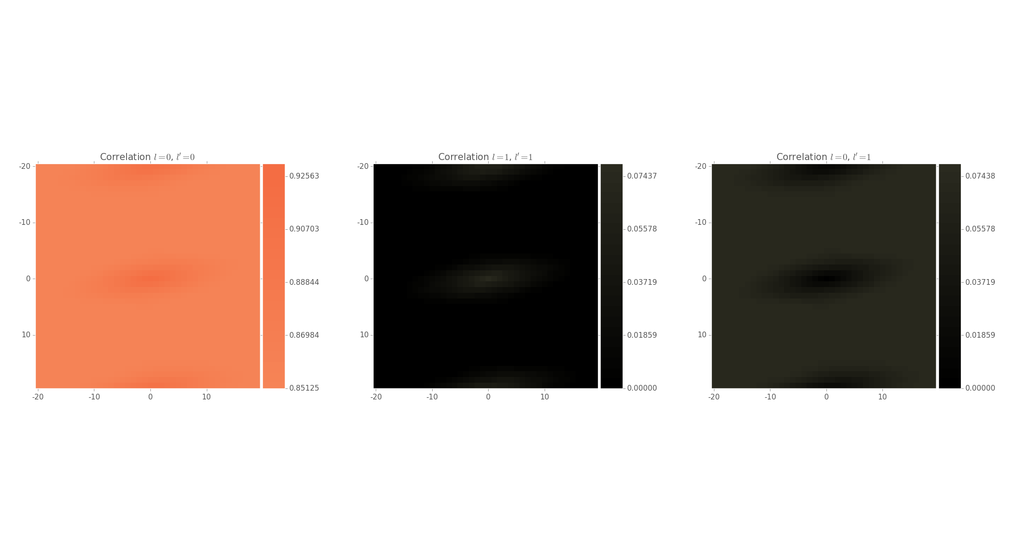

- Use Pair Correlation Functions (PCF) to quantify probability of finding another cluster from a given point

Microstructure Property

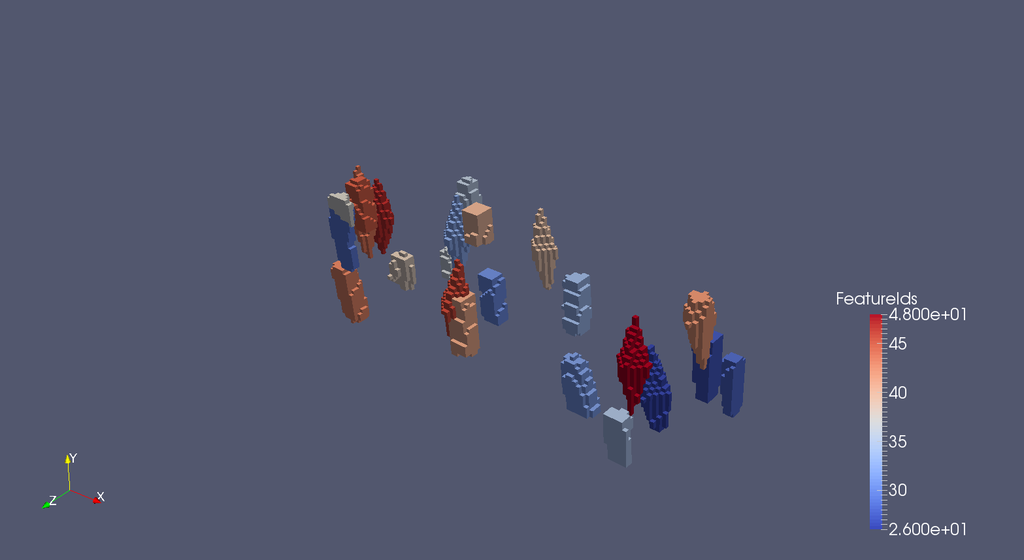

- Fatigue Indicator Parameters (FIP) are used to quantify damage

- We will use the Fatemi-Socie FIP: $FIP_{FS} = \frac{\gamma}{2} ( 1 + k\frac{\sigma}{\sigma_y} )$

- An elastic-plastic constitutive model must be defined

- We are using a linear-elastic model for the stiff particles with: Young’s Modulus of 169 GPa and Poisson Ratio of 0.3

- Investigating the non-local averaged FIP surrounding the particles

- Averaging volume of ~5% particle volume will be used

Simulation

Two-Point Statistics