First Presentation Post (For Comments)

Almambet Iskakov, Robert Pienta

12 00 AM ,Mon, Sep 14 2015

Background

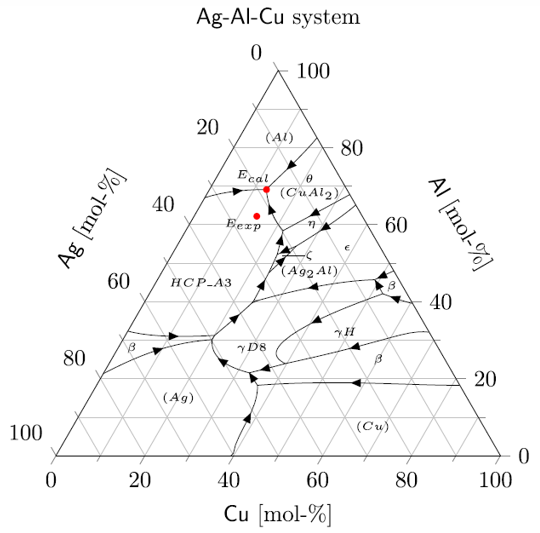

- Directional Solidification of Al, Ag, Cu Eutectic Alloy

- Control structure during solidification process

- Align phases/structures parallel to growth direction

- Achieve desired material properties

Phase-Field Simulation: Solidification

- Solidification Model:

- Simulate growth of phases

- Thermodynamic model

- Concentration model

- Three phase metal

- Varied Parameters: Temperature Gradient and Gradient Velocity

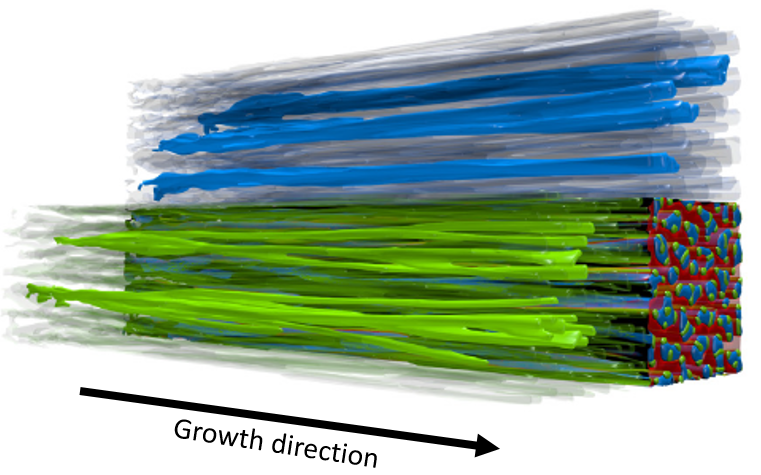

Directional Solidification Visual

Phases evolve parallel to growth direction.

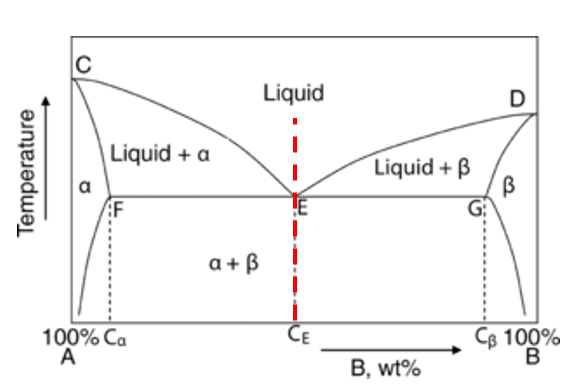

Binary Phase Diagram

- Eutectic mixture:

- Liquid transforms into two different phases

- Lowest melting/freezing temperature

- In this Al, Ag, Cu alloy, the eutectic ratios by mole fraction at 773.6K:

- 18% Ag (25% experimental)

- 69% Al (62% experimental)

- 13% Cu (14% experimental)

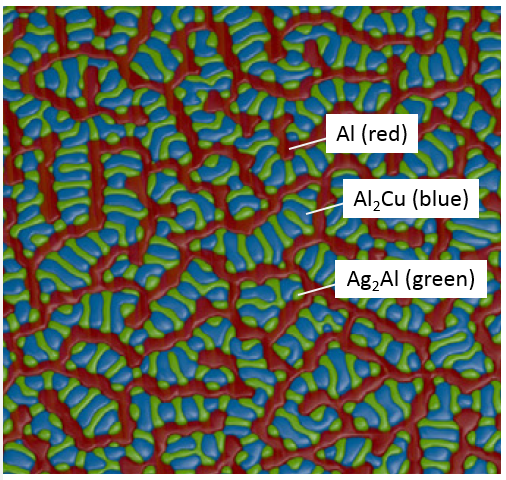

Simulated Microtstructure

- A cross-section of solidified material close to solidification front

- Most continuous phase: Al

- Chained brick-like structure: Al2Cu and Ag2Al

Common Microstructure Patterns

The Data

- More than 20 simulations

- Resolution from 200x200 to over 2000x2000

- Simulated with varied solidification velocities

- Varied volume-fractions of Al, Ag2Al, and Al2Cu

- Plenty of measurements!

- An 800x800x4256 sample has 2.72 billion data points

- This simulation took 16 hours on 13700 cores!

- An 800x800x4256 sample has 2.72 billion data points

Simulation in action

Al = Green, Ag2Al = Orange, and Al2Cu = Blue

Extracting Features

We have already started generating spatial statistics (correlations) for our data

0 = Al, 1 = Ag2Al, and 3 = Al2Cu

Distance-varying Distributions

- The simulated microstructures vary through the course of each simulation

- We can sample the approximate steady-state, solidified structure at various times,

- using the difference between successive spatial statistics

- or just using one of the last time/height steps (assuming that the simulation was run until a steady state was reached)

- We may later consider the changes in spatial statistics over time to help mine the Process-Structure linkages

Computational Plans

Next Steps

- Use dimensionality reduction (DR) over our large space of spatial statistics:

- Conventional PCA

- Newer low-rank approximation DR techniques

- (possibly) Attempt to use locality sensitive hashing

- Model the relationship between our simulated solidification processes

- linear model (regression)

- interpretable

- simple model, unlikely that Eutectoid Al has linear structural relationships

- nonlinear model (kernel methods)

- less interpretable

- complex model, can model complex relationships

- linear model (regression)