Progress Report (Post)

Almambet Iskakov, Robert Pienta

12 00 AM ,Wed, Oct 07 2015

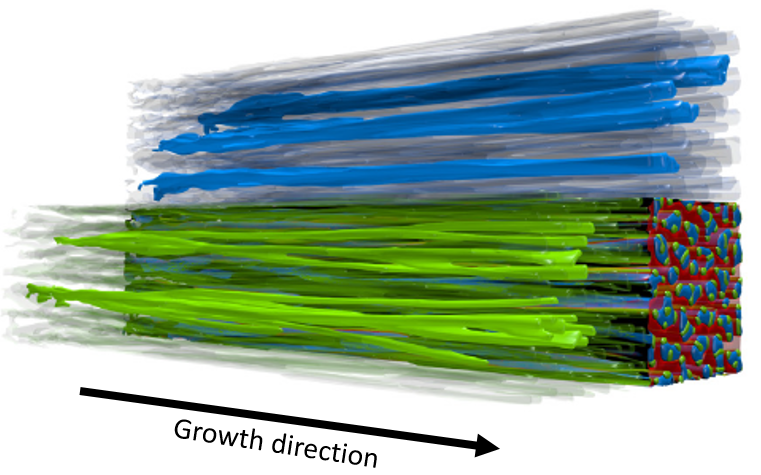

Quick Recap

- Directional Solidification of Al, Ag, Cu Eutectic Alloy

- Made from state-of-the-art simulations

- Multiple solidification velocities and volume-fractions

- Plenty of data, plenty of challenges to overcome

Data: (12x) 800x800x300

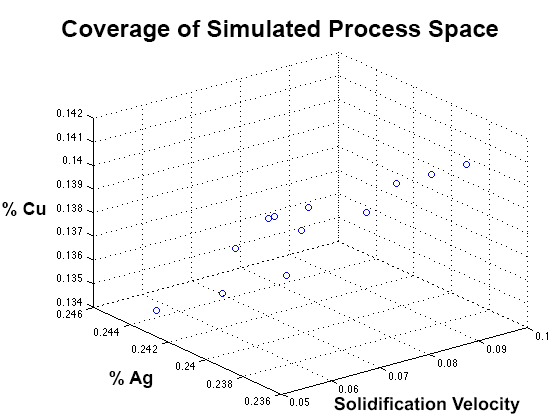

We can characterize these points using:

- Two volume fractions (the third is dependent)

- Solidification velocity

Curious Parameters

- We have more than 12 simulations at this resolution

- 2 have solidification velocities around 0.6

- All other experimental velocities are 0.09 or less

-

Is this suspicious?

- Possibly more data in future

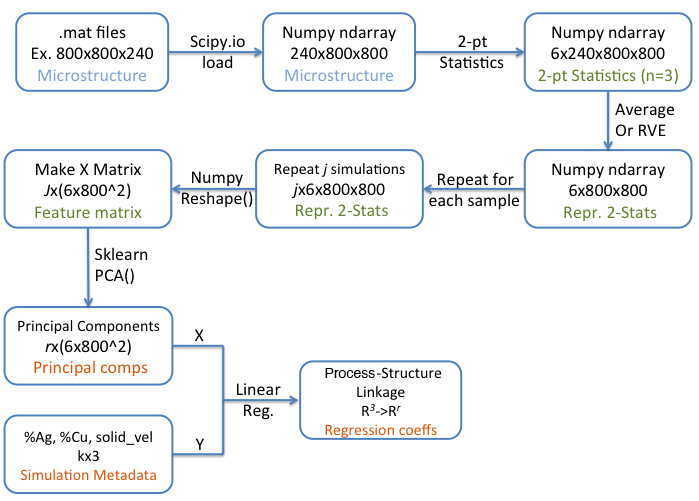

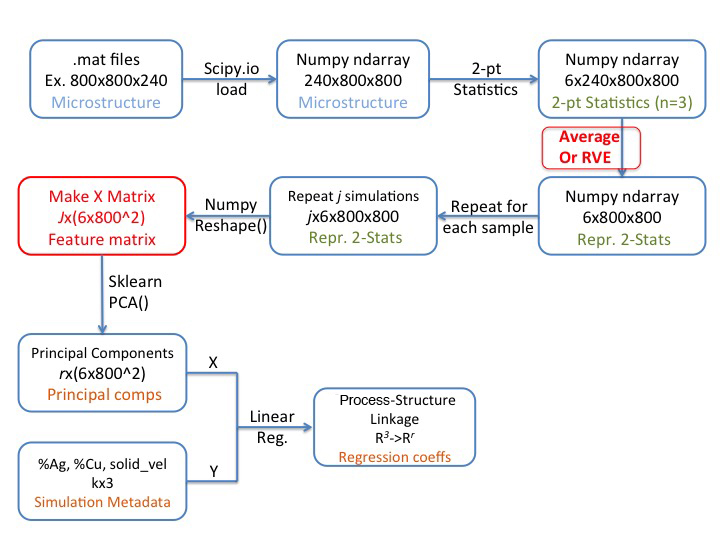

Our Workflow

Steps with unanticipated challenges:

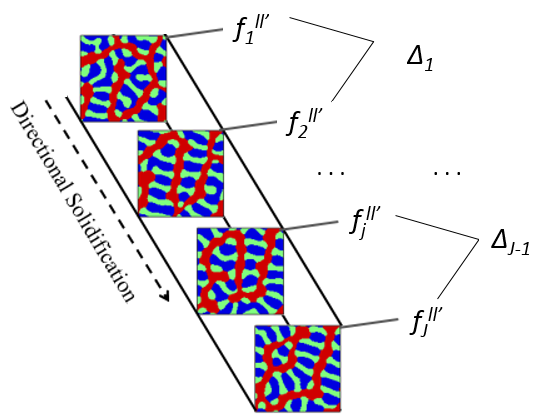

2-Points Everywhere

- 3 phases (0 - Al, 1 - Ag-Al, 2 - Al-Cu)

- Assume periodic microstructure (based on simulation)

- Finding a representative microstructure

* Which microstructure is representative?

* Which microstructure is representative?

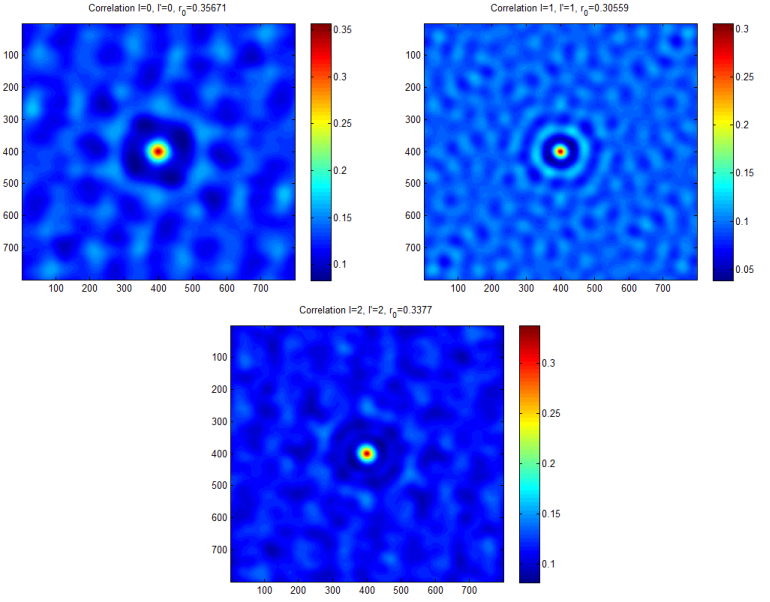

Example two-point statistics (autocorrelation)

Steady-State Solidification

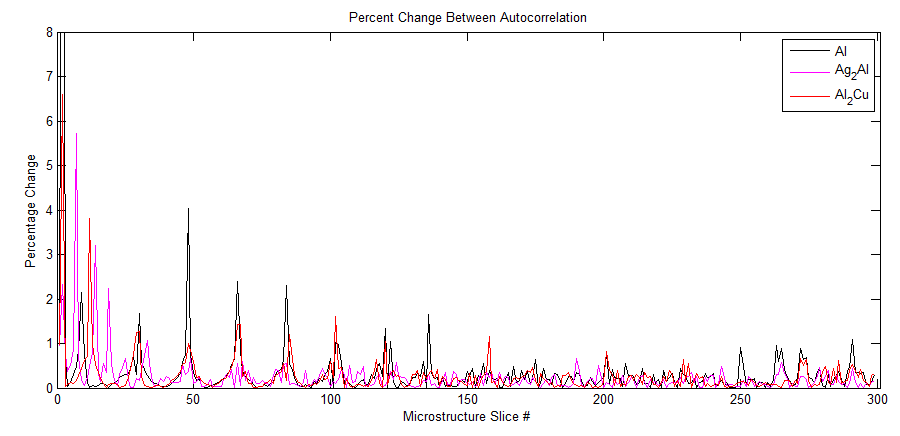

Finding representative microstructure (preliminary method)

- Compute the difference between spatial correlations to identify convergence/trends

Comparing autocorrelation

- High initial variation; steady in full simulation result?

- Explore other methods (RVE, etc.)

PCA

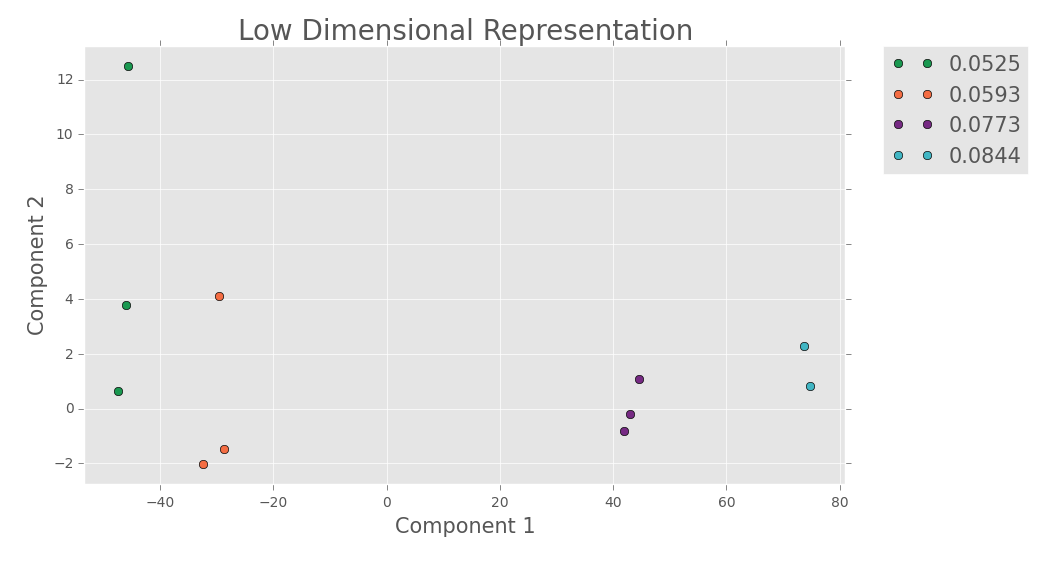

Simulated Volumes in PCA-Component-Space

(grouped by solidification vel.)

(grouped by solidification vel.)

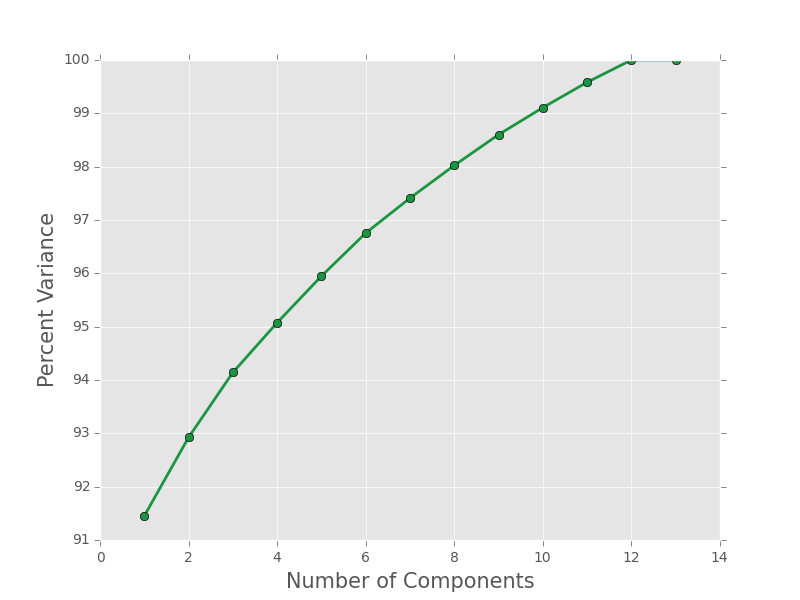

Cumulative Variance by PCA Component

Encouraging singular-value fall-off characteristics

Encouraging singular-value fall-off characteristics

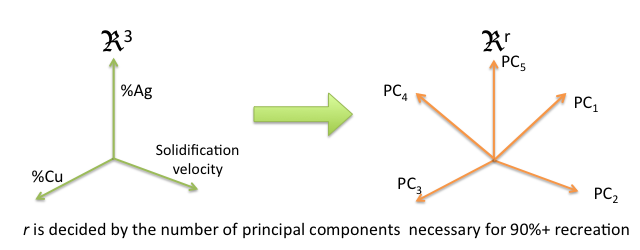

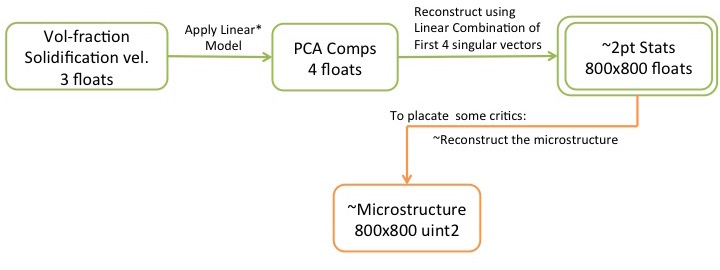

Linkage Overview

Multivariate regression problem:

Linkage and its application

From a vol-fraction and solidification vel. to “a microstructure”.

Ongoing Work

- We are currently working on cross-validation for our pipeline.

-

Originally wanted k-fold cross validation, but…

-

That’s leave-one-out for ~10 data points.

-

- We have not completed the reconstruction code, but can produce everything up to it.

Challenges

- Representing each volume with a microstructure

- Choosing an RVE

- Doing an expensive 3D 2-pt statistic

- Choosing which correlations to use as PCA inputs

- No control over simulation data